ELECTRONIC MANUFACTURER SERVICES

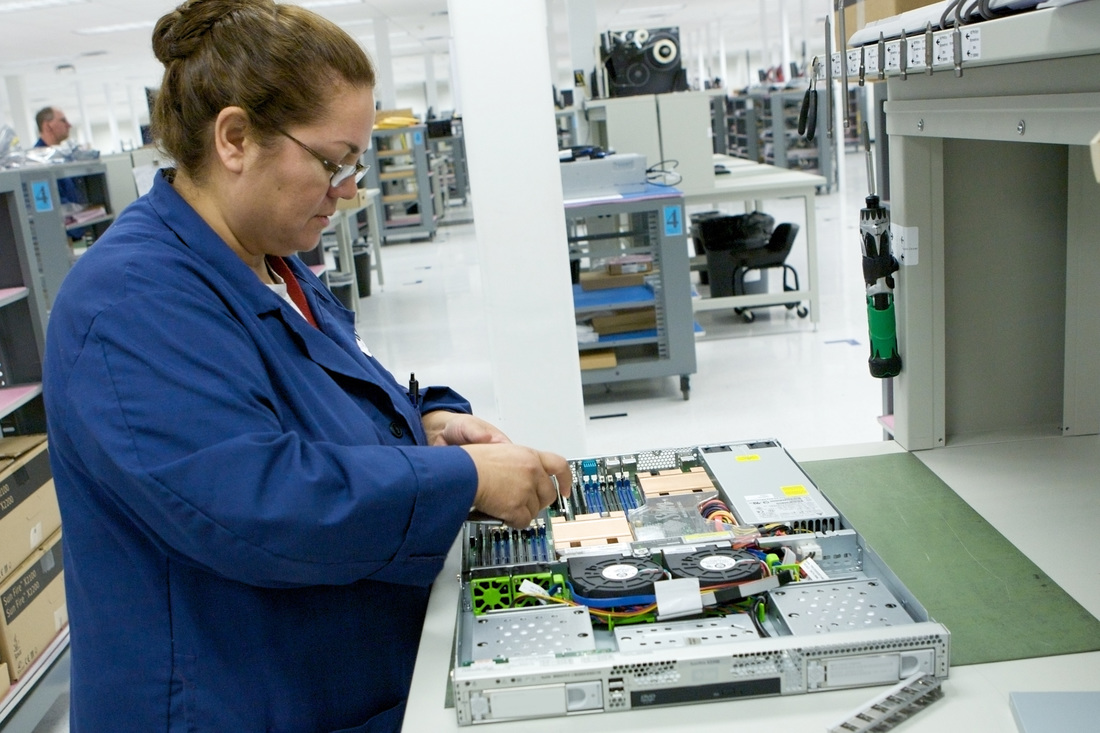

We recognize that your top priority is to satisfy your clients. We are well-aware of the importance for you to have a trustworthy, reliable partner. Let Commercial Solution JFR handle the numerous aspects and processes manufacturing involves, from start to finish, all at one single shop. We give you the PEACE of MIND and free up your resources to pursue your GOALS.

Commercial Solutions JFR offer comprehensive and integrated design and manufacturing services to optimize our clients' operations and time to market, from initial product design to volume production. We are skilled in servicing OEMs and ODMs of a wide variety of industries including automotive, industrial control equipment,

telecommunication, power management, video / audio /entertainment, computer peripherals, and consumer electronics.

Our Total Value-Added Package begins with quality control, through product development, supply chain and material management, prototyping, production planning and manufacturing, test strategy, logistics services, and client service and support.

Quality Control

Quality, client satisfaction, and continue improvement are our primary focus. At Commercial Solutions JFR strict Quality Control (QC) systems and standards are executed at every stage to minimize risks and to ensure safety and reliability of our products and services, which in turn enable us to fulfill and exceed clients' expectation.

Product Design and Development

Commercial Solutions JFR offers a broad range of Electrical, Mechanical, and Software Engineering Services. Our design team is ready to work as part of your design engineering staff to make your design a reality. Our designers have extensive knowledge and expertise to help you with high complexity products. Our Design Services are tightly coupled with our manufacturing and test systems to ensure the design is measured up to your specifications and satisfaction.

Some of our design services include:

Supply Chain and Materials Management

Our Supply Chain Management Services coordinate the material support functions through efficient prosecution, global procurement database, and strategic supplier relationships to offer in-depth material analysis, flexible supply chain strategies, personal service, and aggressive world class material cost.

Commercial Solutions JFR Advantages:

PROTOTIPING

We can meet all of your prototype needs. Our dedicated prototype lab provides quick-turn, hand and machine assembled prototypes to meet short design cycle times. Parts procurement can be handled in a variety of ways, from acquiring all components needed to assemble your prototypes, to using consigned components exclusively. Our highly trained engineering and manufacturing personnel oversee prototype assembly to ensure design specification conformance prior to the start of production.

Commercial Solutions JFR Advantages:

Commercial Solutions JFR offer comprehensive and integrated design and manufacturing services to optimize our clients' operations and time to market, from initial product design to volume production. We are skilled in servicing OEMs and ODMs of a wide variety of industries including automotive, industrial control equipment,

telecommunication, power management, video / audio /entertainment, computer peripherals, and consumer electronics.

Our Total Value-Added Package begins with quality control, through product development, supply chain and material management, prototyping, production planning and manufacturing, test strategy, logistics services, and client service and support.

Quality Control

Quality, client satisfaction, and continue improvement are our primary focus. At Commercial Solutions JFR strict Quality Control (QC) systems and standards are executed at every stage to minimize risks and to ensure safety and reliability of our products and services, which in turn enable us to fulfill and exceed clients' expectation.

- incoming Quality Control

- In-process Production Quality Control (IPQC)

- Finished Goods Quality Control (FGQC)

- Electro-Static Discharge (ESD) control

- Intelligent SMT feeders to prevent loading of incorrect parts

- In-line Solder Paste Inspection (SPI)

- Real time process feedback via AOI (Automatic Optical Inspection)

- Automated Testing systems

- X-ray quality inspection

- In-depth knowledge of CE, UL standards

- Identification and tracking system

- Return Merchandise Authorization (RMA)

Product Design and Development

Commercial Solutions JFR offers a broad range of Electrical, Mechanical, and Software Engineering Services. Our design team is ready to work as part of your design engineering staff to make your design a reality. Our designers have extensive knowledge and expertise to help you with high complexity products. Our Design Services are tightly coupled with our manufacturing and test systems to ensure the design is measured up to your specifications and satisfaction.

Some of our design services include:

- Advise on screening techniques such as HALT (Highly Accelerated Life Test), HASS (Highly Accelerated Stress Screening), ESS (Environmental Stress Screening)

- Design performance improvement, optimization and design transformation for efficient manufacturing

- Flying Probe, ICT and Functional Test Development

- Knowledge of Standards such as CE, UL, etc.

- Mechanical Design using AutoCAD, Pro-E, SolidWorks, etc.

- PCB Layout, PCB Panel optimization

- Reduced time-to-market through speedy and flexible engineering

Supply Chain and Materials Management

Our Supply Chain Management Services coordinate the material support functions through efficient prosecution, global procurement database, and strategic supplier relationships to offer in-depth material analysis, flexible supply chain strategies, personal service, and aggressive world class material cost.

Commercial Solutions JFR Advantages:

- Forecasts every component to assure availability

- Analyzes Bill of Materials (BOM) and production documentation to ensure component uniformity and data integrity

- Recommends alternative components to reduce cost while maintaining product quality

- Provides expertise and purchasing power through extensive global supplier relationships to reduce overall material cost

- Performs continuous supplier development and assessment to ensure supplier stability, delivery capabilities, and compliance

- Implements comprehensive documentation system to provide a range of traceability from simple to complex:

- Batch / Serial Number

- Brand

- Country of origin

- Every part by supplier

- Lot Specific

- Commercial Solutions JFR offers a broad range of Electrical, Mechanical, and Software Engineering Services. Our design team is ready to work as part of your design engineering staff to make your design a reality. Our designers have extensive knowledge and expertise to help you with high complexity products. Our Design Services are tightly coupled with our manufacturing and test systems to ensure the design is measured up to your specifications and satisfaction.

- Advise on screening techniques such as HALT (Highly Accelerated Life Test), HASS (Highly Accelerated Stress Screening), ESS (Environmental Stress Screening)

- Design performance improvement, optimization and design transformation for efficient manufacturing

- Flying Probe, ICT and Functional Test Development

- Knowledge of Standards such as CE, UL, etc.

- Mechanical Design using AutoCAD, Pro-E, SolidWorks, etc.

- PCB Layout, PCB Panel optimization

- Reduced time-to-market through speedy and flexible engineering

PROTOTIPING

We can meet all of your prototype needs. Our dedicated prototype lab provides quick-turn, hand and machine assembled prototypes to meet short design cycle times. Parts procurement can be handled in a variety of ways, from acquiring all components needed to assemble your prototypes, to using consigned components exclusively. Our highly trained engineering and manufacturing personnel oversee prototype assembly to ensure design specification conformance prior to the start of production.

Commercial Solutions JFR Advantages:

- Establishes solid supplier relationships to enable parts availability and cost effective pricing

- Offers fast and efficient prototype assembly to reduce design cycle time

- Provides one single shop for electrical and mechanical prototypes to simplify communication and reduce time-to–market.

- Contributes Design for Manufacturability (DFM) and Testability (DFT) recommendations to improve manufacturability of the product, which ultimately reduces time to market